URBAN [RE] MEDIATION

Seattle, Washington, USA

“The healing process can be beautiful. Let it be. ”

PROJECT SCOPE

As part of the Graduate Comprehensive studio, the program given to us was to design an air and maritime museum.

SITE

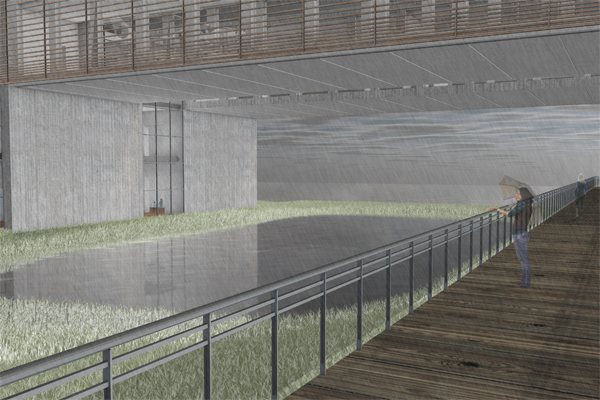

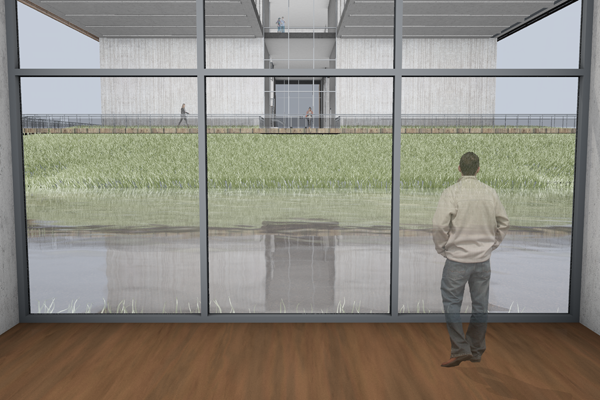

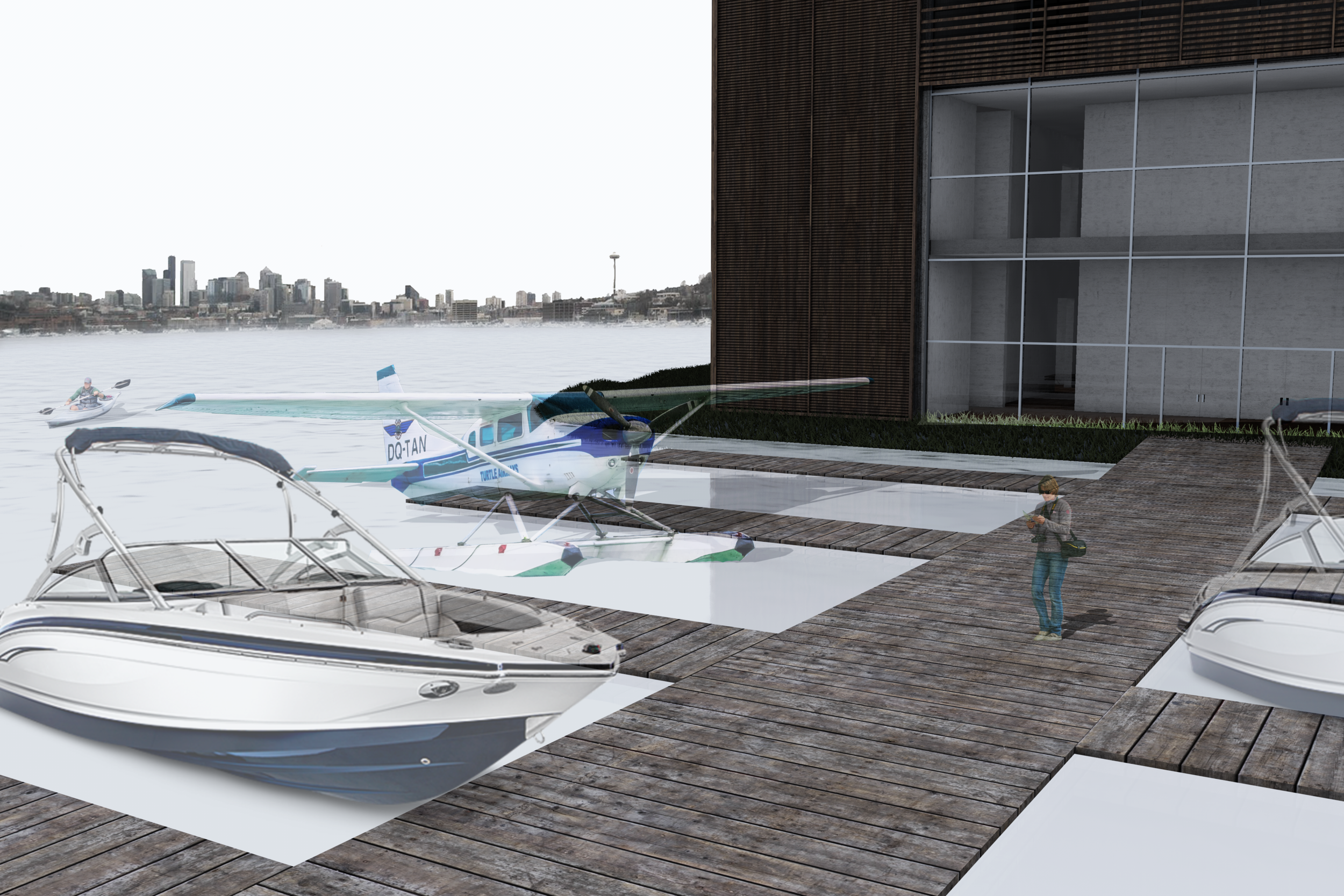

The site chosen was at the Gas Works park in Seattle, Washington. A study of the history of the site showed that it was in need of remediation due to contamination by chemincals like Lead, Phosphorus etc. Thus, the my group’s program evolved from a museum for aquatic aviation and maritime exhibits. The building not only had to create a phenomenological connection with program but also an environmentally responsive connection with the site. The soil and water which are highly contaminated required us to develop an architectural system on the site that will not only remediate the soil during the initial construction, but would continue treatment throughout the life of the building. Thus parts of the building were lifted off the ground still allowing access to the ground in other parts responding the aquatic aviation. The portion of the building lifted off the ground allowed for the construction of a bio remediation basin which would help in purification and filteration of the site.

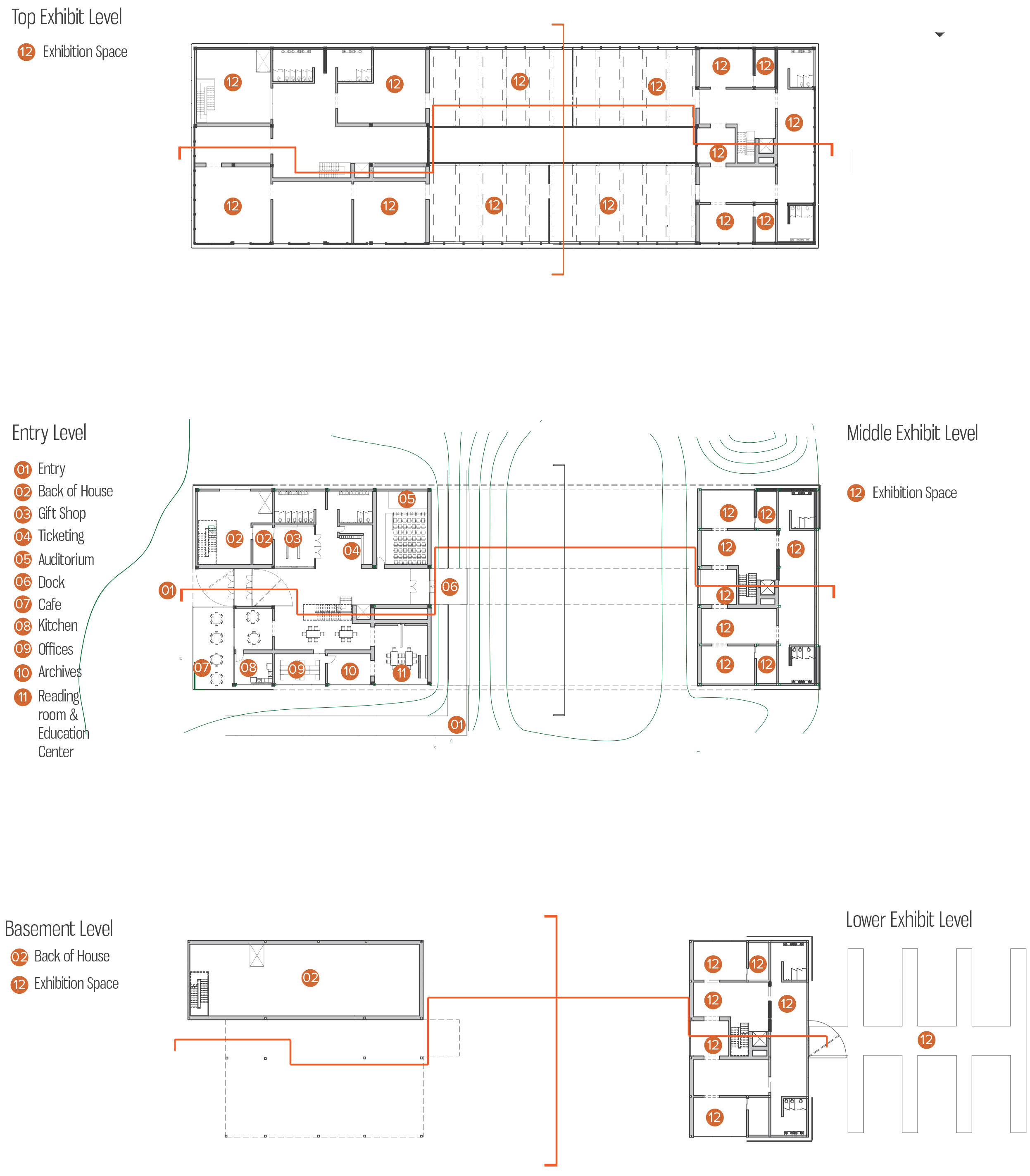

STRUCTURE

The three levels of the building are shown below. The building in the 2 lower levels are separate connected by the third level above. The top level is made of Vierendeel trusses running along the length of the passage.

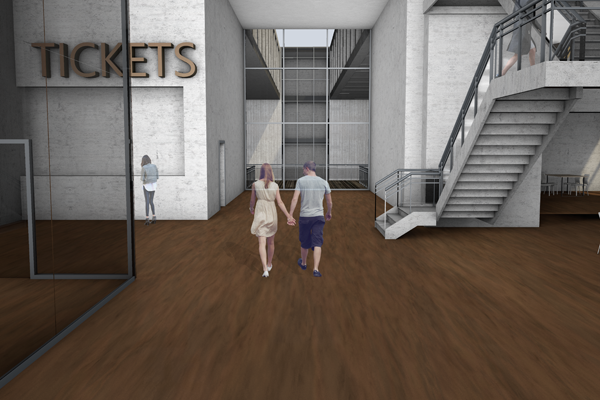

The airy 3 tiered structure gives visitors a sense of the freedom experienced by aviators who could land anywhere on sea or on land. Its structure has been designed to allow large exhibits to be installed at any location in the building, creating some surprisingly spacious gallery opportunities at the higher levels.

SYNERGY

Most importantly, the building and the site exist in a state of synergy. Rain screens and terrain lead to a collection area called the bioremediation basin. The basin water is led through soil and other organic filters. Most of the clean water is then redirected to allow for ground water recharge. Some of the purified water is also run through a heating circuit. This hot water is then used to heat the building by circulating it within the structural beams via copper tubing. A highlight of this project was demonstrating this concept’s viability with a dynamic, functional model.